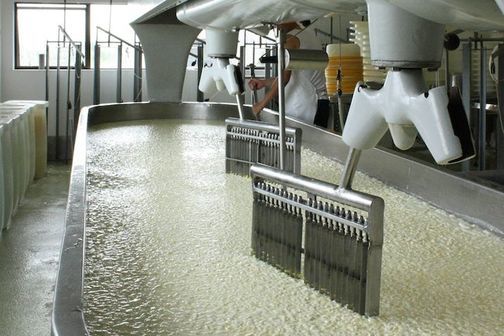

Cheesemaking is the controlled process of removing water from milk. This process concentrates the milk’s protein, fat and other nutrients and increases its shelf life. Cheesemaking is one of the earliest examples of biotechnology.

An ancient biotechnology

Cheesemaking is an ancient biotechnology that dates back to the domestication of animals. It is thought that it was probably first discovered by observing the accidental souring of milk and then pressing and salting the solid curd to preserve it for later consumption. Find out more about some early examples of biotechnology in our article on ancient biotechnology.

Cheesemaking principles

Bacteria acidify milk

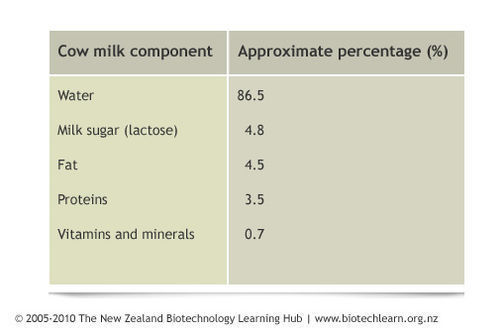

Acidifying (souring) milk helps to separate the curds and whey and control the growth of undesirable bacteria in cheese. Usually special ‘starter’ bacteria are added to milk to start the cheesemaking process. These bacteria convert the lactose (milk sugar) to lactic acid and lower the milk’s pH.

There are two types of bacteria used for this process:

- Mesophilic bacteria thrive at room temperature but die at higher temperatures. They are used to make mellow cheeses, such as Cheddar, Gouda and Colby.

- Thermophilic bacteria thrive at higher temperatures, around 55 °C, and are used to make sharper cheeses such as Gruyère, Parmesan and Romano.

Enzymes speed up coagulation

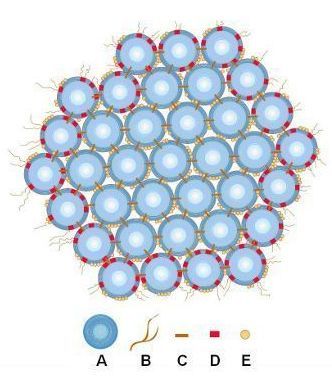

Some cheeses are curdled only by acidity. For example, paneer cheese is made using lemon juice to curdle the milk and cottage cheese is made using mesophilic bacteria. However, for most cheeses, rennet is also added to the milk after a starter bacteria. Rennet is a mixture containing the active enzyme chymosin. Rennet speeds up the coagulation of casein and produces a stronger curd. It also allows curdling at a lower acidity, which is important for some types of cheese.

Casein proteins coagulate

Sources of rennet

Rennet comes from the stomachs of young mammals that have a diet of mostly milk. Rennet from calf stomachs was the major source of chymosin until the 1960s when it was predicted that increasing demand for meat and increasing cheese production would lead to a shortage of calves and therefore a shortage of rennet. This led to the development of substitutes including extracts from adult cows and pigs, fungi and, more recently, microorganisms that have been genetically modified (GM) to yield GM rennet. GM rennet is the most commonly used today because it is the most cost-effective to produce.

Releasing the whey

After separating curds and whey, further processing of the curds helps release more of the whey trapped in the network of micelles before it is drained away. The exact processing steps vary depending on the type of cheese. However, generally, the curds are captured, pressed and moulded to form blocks of cheese.

Historically, whey was considered a waste product of cheesemaking. However, growing concern over the environmental impact of its disposal encouraged research to better understand the properties and potential uses of whey. Increasing scientific understanding and technological advances have led to a wide range of uses for whey and established it as a valuable coproduct of the cheese industry, find out more about other uses of whey.

Ripening the cheese

Cheese is left to ripen, or age, in a temperature and humidity-controlled environment for varying lengths of time depending on the cheese type. As cheese ripens, bacteria break down the proteins, altering the flavour and texture of the final cheese. The proteins first break into medium-sized pieces (peptides) and then into smaller pieces (amino acids). In turn, these can be broken down into various, highly flavoured molecules called amines. At each stage, more complex flavours are produced.

During ripening, some cheeses are inoculated with a fungus such as Penicillium. Inoculation can be either on the surface (for example, with Camembert and Brie) or internally (for example, with blue vein cheeses). During ripening, the fungi produce digestive enzymes, which break down large protein molecules in the cheese. This makes the cheese softer, runny and even blue.

Cheese comes in many varieties of different styles, textures and flavours, find out more on creating some of these different cheese characteristics.

Transgenic cow research reveals potential to increase cheese yield

AgResearch’s transgenic cow research has produced transgenic cows with extra bovine kappa casein genes inserted in their genome. This resulted in increased kappa casein in their milk. Increased kappa casein levels are associated with better cheesemaking properties, higher cheese yield and higher calcium content.

Useful links

Chymosin production

Learn more about chymosin, a very important enzyme that is also a genetically modified organism in this 2017 podcast and article on the UK Royal Society of Chemistry website.

A history of cheese

Read about the history of cheese from its early beginnings to the present in this magazine-style article from The Nibble.