Sialons – based on the elements silicon (Si), aluminium (Al), oxygen (O) and nitrogen (N) – are a relatively new family of advanced ceramic materials. Some have high thermal resistance, some have extreme hardness and others have extreme toughness.The presence of nitrogen in the chemical structure of the ceramic is what makes the difference in terms of the properties the sialons show.

Materials scientists working at Industrial Research Limited (IRL) in Wellington, under the guidance of Dr Ian Brown, have developed an oxygen-enriched sialon called O-Sialon.

Its discovery came about as the result of what Ian describes as a “controlled accident”.

In order to improve the plasticity of an experimental sialon mix, Ian added some clay powder.

On analysing the sialon produced, it was found to have a little more oxygen present and a little less nitrogen.

This ‘new’ formulation was named O-Sialon, and it displayed excellent thermal shock resistance as well as being resistant to high temperature oxidation.

Nature of science

Sometimes discoveries in science are a result of unplanned and unforeseen laboratory procedures and processes. In the development of O-Sialon, Dr Ian Brown just happened to include clay into the mix of starting materials. It proved to be the ‘missing’ ingredient needed to turn failure into success.

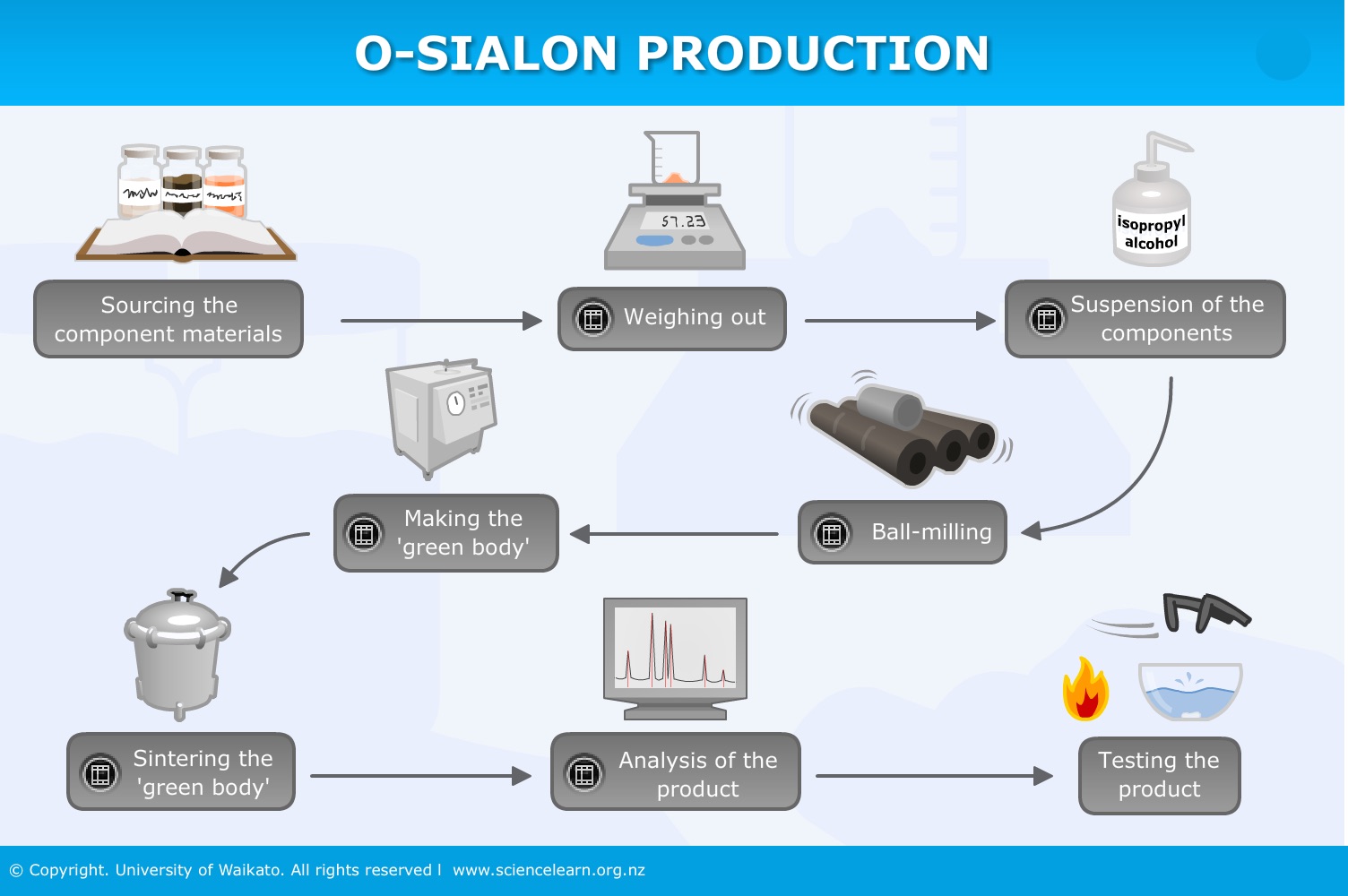

The process of carefully blending clay, silica sand and silicon metal and heating to 1,500°C in an atmosphere of nitrogen has been patented in conjunction with an industrial partner.

O-Sialon is hard and tough with excellent thermal shock resistance. It can withstand rapid heating to high temperatures followed by rapid cooling over many cycles with little structural damage.

These properties have led to its use in the construction of pipes, tubes and conduits to contain and channel non-ferrous molten metals like aluminium and its alloys.

Body armour

One of the research projects being conducted by Ian’s team at IRL is focused on developing lightweight O-Sialon body armour. The hardness, toughness, relative low density and virtual indestructibility of this advanced ceramic make it a prime candidate for such an application.

The specific goal of the advanced ceramics programme developed by Ian is “to develop advanced ceramic materials and technologies related to their production and fabrication, to meet New Zealand’s current and future needs for these materials”.

Related content

Explore further the uses for advanced ceramics and what are ceramics.

Activity idea

In Sialons – Ian Brown video clips: watch videos of Dr Ian Brown talking about sialons and then answer a series of graded questions related to the content.